Commercial Spring Roll Wrapper Machine for Automatic & Semi-Automatic Production

Automatic Spring Roll Wrapper Machine Spring roll sheet making machine is mainly used for making Spring roll sheets, lumpia wrappers, samosa sheets, thin crepes or pancakes, and Chinese roast duck cakes.

Automatic & Semi-Automatic Spring Roll Wrapper Machine / Sheet Making Machine

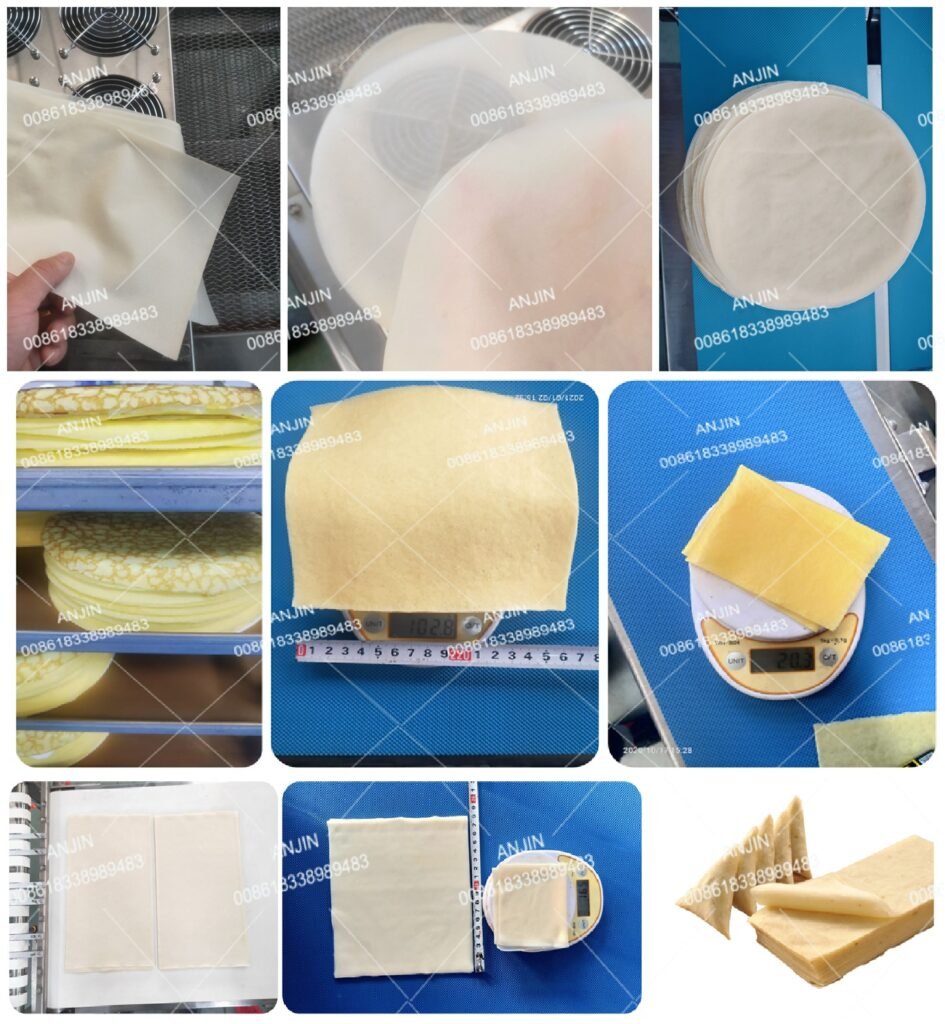

Our spring roll wrapper machine and spring roll sheet making machine are designed for bakeries, frozen food factories, and catering businesses. The automatic spring roll machine model delivers up to 6,000 wrappers per hour with minimal labor, while our semi-automatic spring roll machine offers flexible production for small to medium-scale operations. Both machines maintain uniform thickness, precise size control, and consistent quality for every wrapper.

Lumpia Wrapper Machine & Spring Roll Skin / Pastry Equipment

Also known as a lumpia wrapper machine in the Philippines, our equipment produces thin pastry sheets. These sheets are uniform. Because of this, they are perfect for lumpia, egg rolls, and mini pies. Moreover, the spring roll skin machine supports multiple recipes. For example, it can handle fresh dough. It also supports frozen dough. As a result, it meets diverse production needs. Therefore, this machine suits food producers who require flexibility and quality.

Industrial Spring Roll Sheet Line & Commercial Spring Roll Production Solutions

For large-scale operations, we offer a full spring roll production line—including spring roll wrapper processing, cooling, stacking, and packaging. Our industrial spring roll sheet line integrates with automatic filling and folding systems for ready-to-cook products.

Food Processing Machine for Asian Cuisine

Our food processing machines are specially designed to meet the diverse needs of Asian cuisine. From dough preparation to wrapper forming, our equipment adapts to local recipes and production requirements.

Fresh Spring Rolls Production Equipment

For fresh spring rolls, our machines ensure thin, elastic wrappers with consistent quality. They support flexible batch sizes and quick recipe changes to suit different market demands.

Lumpia Processing Steps & Wrapper Making

The lumpia production line includes dough mixing, sheet forming, cutting, and stacking. Each step is optimized to maintain wrapper integrity and streamline packaging.

Application:

Widely used in chain stores, central kitchens, food factories, restaurants, fast food restaurants, and other units.

Feature:

- An advanced temperature control system that accurately displays and controls the temperature. (CE safety standards)

- It boasts a high heat utilization rate with minimal heat loss, fulfilling the goals of energy conservation and environmental protection.

- Operators can adjust the temperature and thickness easily.

Parameter data:

| Model | AJ-3620 | AJ-5029 | AJ-8045 | AJ-12060 |

| Voltage | 380/220V(50/60HZ) | |||

| Dia. of heating Cylinder | 400mm | 500mm | 800mm | 1200mm |

| Power | 8/10kw or gas | 18kw or gas | 40kw or gas | 59kw or gas |

| Capacity | 500-1000pcs/h | 1000-1500pcs/h | 3500pcs/h | 9000pcs/h |

| Dimension | 4100*950*1350mm | 5200*950*1350mm | 6200*1100*1600mm | 6500*1300*2300mm |

| Rotating speed | 1-2.5r/min | 1-2.5r/min | 1-3r/min | 1-3r/min |

| Weight | 330kg | 520kg | 1000kg | 1750kg |

| Size of the Sheet ( Max.) | 200mm | 300mm | 450mm | 600mm |

| Thickness of the Sheet | 0.5-2.0mm | |||

| Note | Capacity based on spring roll sheet size, | |||

| The actual capacity is subject to the quotation list. | ||||

FAQ: About spring roll sheet making machine

Q1: Does this machine support making spring roll wrappers for fresh and frozen applications?

A1: Yes. Our commercial spring roll machine supports fresh wrapper production and frozen wrapper lines with integrated cooling systems.

Q2: Can I use the same equipment for lumpia and Chinese spring rolls?

A2: Absolutely. The lumpia wrapper machine and Chinese food wrapper machine are essentially the same, with minor recipe adjustments.

Q3: The spring roll wrapper making machine can use what kind of flour to make the batter paste?

A3: This machine is most suitable for working with wheat flour.

Q4: How does the spring roll pastry machine work?

A4: The spring roll skin machine typically mixes flour and water to create a batter. After preparing the batter, the machine proceeds to spread it uniformly onto a heated surface, where it cooks to perfection and takes shape as the wrapper. After cooking, the machine automatically removes the wrapper from the surface.

Q5: What is the production capacity of the automatic spring roll machine?

A5: Production capacity varies based on the spring roll sheet equipment’s size and design. Capacities can range from a few hundred to thousands of wrappers per hour.

Q6: I’m a new beginner to spring roll wrapper making, what model should I choose?

A6: Please provide your product specifications and hourly output. We will create a flow diagram, and our engineer will design a custom factory based on your location.

Video for reference: