Automatic Spring Roll Sheet Machine Samosa Pastry Forming Machine

Automatic Spring roll sheet machine is mainly used for making Spring roll sheets, lumpia wrappers, samosa sheets, thin crepe or pancakes, and Chinese roast duck cakes.

Application of Spring Roll sheet making machine:

Widely used in chain stores, central kitchens, food factories, restaurants, fast food restaurants, and other units.

Features of Samosa Pastry Forming Machine :

- A temperature control system that accurately displays and controls the temperature. (CE safety standards).

- It boasts a high heat utilization rate with minimal heat loss, fulfilling the goals of energy conservation and environmental protection.

- The machine has a low production cost and a simple operating system, allowing it to be operated by a single person, thereby saving on labor.

- Temperature and thickness can be adjusted.

Spring Roll Sheet Processing Steps:

Batter paste mixing – batter filter – batter printing to the baking drum – sheets baking – cooling conveyor – counting and folding part – finished product conveyor belt – packing machine.

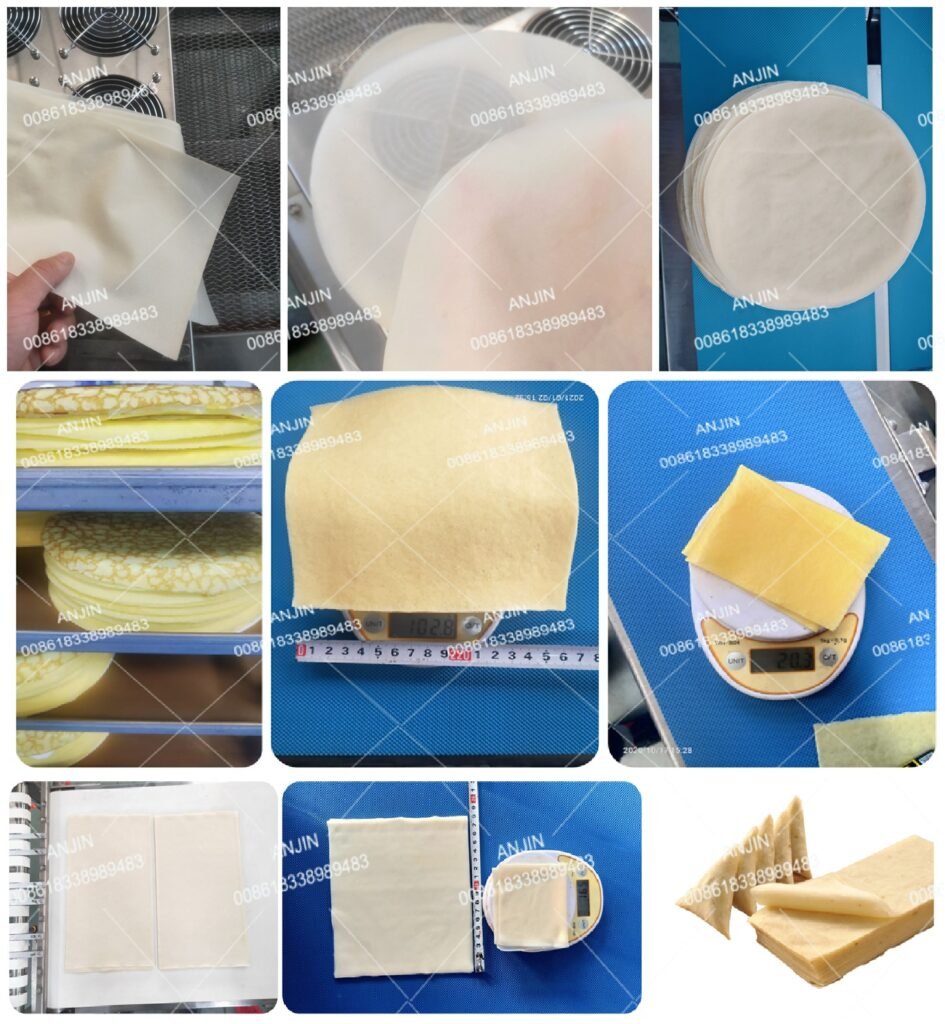

Finished Products of Spring Roll Pastry:

Parameter Data of Spring Roll Wrapper Maker:

| Model | AJ-3620 | AJ-5029 | AJ-8045 | AJ-12060 |

| Voltage | 380/220V(50/60HZ) | |||

| Dia. of heating Cylinder | 400mm | 500mm | 800mm | 1200mm |

| Power | 8/10kw or gas | 18kw or gas | 40kw or gas | 59kw or gas |

| Capacity | 500-1000pcs/h | 1000-1500pcs/h | 3500pcs/h | 9000pcs/h |

| Dimension | 4100*950*1350mm | 5200*950*1350mm | 6200*1100*1600mm | 6500*1300*2300mm |

| Rotating speed | 1-2.5r/min | 1-2.5r/min | 1-3r/min | 1-3r/min |

| Weight | 330kg | 520kg | 1000kg | 1750kg |

| Size of the Sheet ( Max.) | 200mm | 300mm | 450mm | 600mm |

| Thickness of the Sheet | 0.5-2.0mm | |||

| Note | Capacity based on spring roll sheet size, | |||

| The actual capacity is subject to the quotation list. | ||||

FAQ : About spring roll sheet making machine

Q1: The machine can use what kind of flour to make the batter paste?

A: This machine is most suitable for work with wheat flour.

Q2: How does the machine work?

A: The machine typically mixes flour and water to create a batter. After preparing the batter, the machine proceeds to spread it uniformly onto a heated surface, where it cooks to perfection and takes shape as the wrapper. After cooking, the machine automatically removes the wrapper from the surface.

Q3: What is the production capacity of the machine?

A: Production capacity varies based on the machine’s size and design. Capacities can range from a few hundred to thousands of wrappers per hour.

Q4: I’m a new beginner to spring roll wrapper making, what model I should choose?

A: Please provide your product specifications and hourly output. We will create a flow diagram and our engineer will design a custom factory based on your location.

Video for reference:

Related solutions of Spring Rolls:

Fully automatic spring roll production line 3000-7000pcs/h

Semi-automatic spring roll production line 1500-2000pcs/h