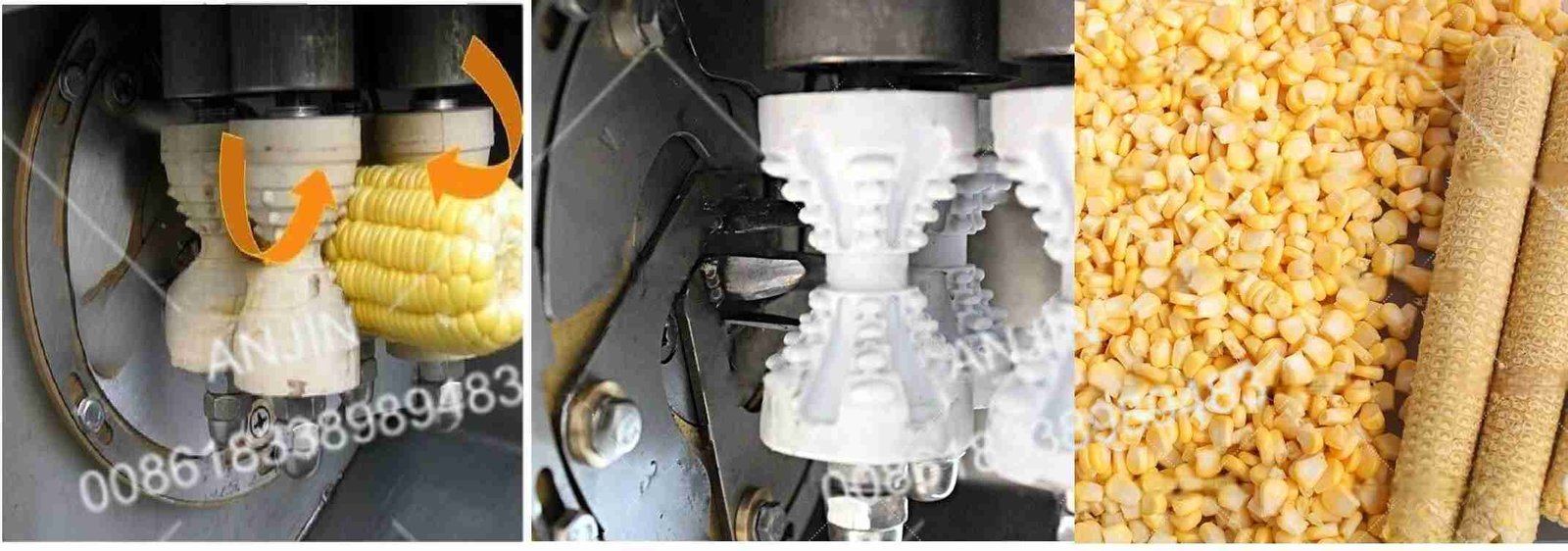

2. The conveying rubber wheel is made of a special material that is soft and elastic to ensure that the corn kernel skin is not damaged during the conveying and clamping process.

3. The cutting process uses a high-speed rotating five-blade knife, which is controlled by centrifugal force and close to the corn cob, ensuring that the kernel incision is smooth and the depth is adjustable during the cutting process.

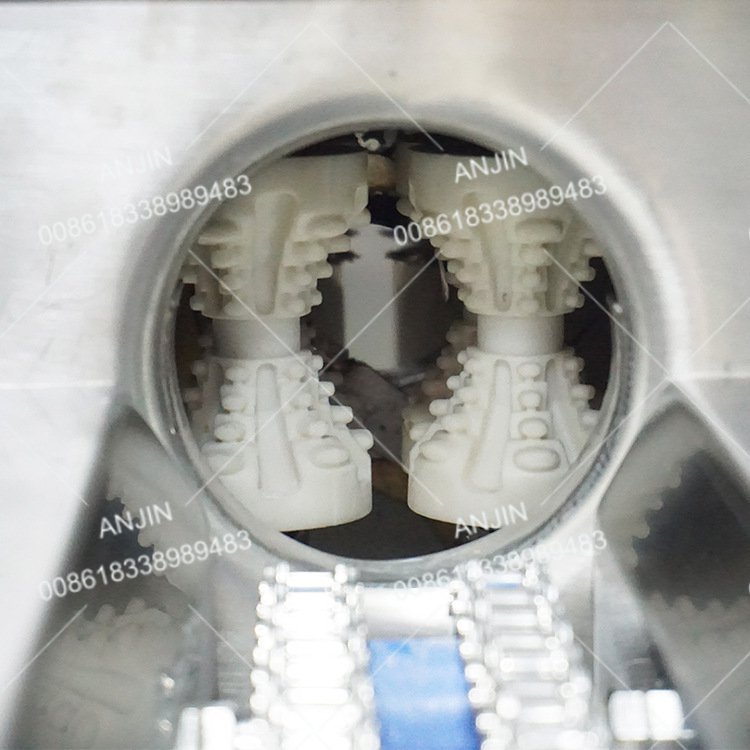

Machine working principle:

Separate corn kernels and corn stalks. The depth of corn threshing can be adjusted according to the size of the corn cobs. It is suitable for threshing all kinds of fresh corn. It has high threshing efficiency and a threshing rate of 98%. It is suitable for use in factories and clean vegetable distribution centers.

Convenient feeding

Adaptable

High removal rate

Reasonable mechanical design

Long tool life

Easy to use and low loss rate

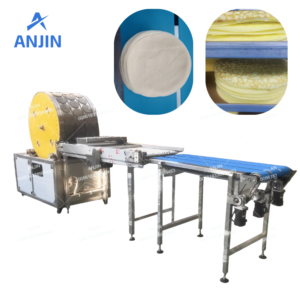

| Model | Dimension | Weight | Capacity | Voltage |

| AJ-CT268 | 630x620x1250mm | 100kg | 500-600KG/HR | 220V 50HZ 1PH |

| AJ-CT368 | 1250*620*1250mm | 120kg | 500-600KG/HR |