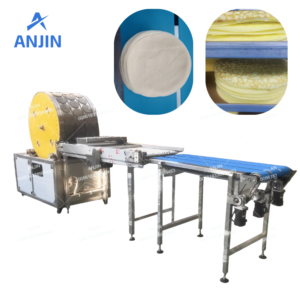

Automatic Cocoa Powder Processing Machine Production Line

Cocoa Power Processing flow:

Cocoa Bean Roasting – cocoa bean skin peeling machine – Cocoa liquor grinding machine – Cocoa liquor hydraulic oil press machine – Cocoa cake crushing machine – Cocoa powder grinding– Cocoa powder packing.

A:Natural cocoa powder is a powder obtained by degreasing and grinding without adding any additives. The PH value is 5.4-5.7, which is acidic. It is mainly used for the processing of natural chocolate and other foods. The alkalized cocoa powder is powder obtained by degreasing and grinding after acidification, which has been neutralized. by adding edible alkali during cooling and stirring, the PH value is 6.8-7.2, which is mainly used for the processing of chocolate drinks, and is not suitable for the production of chocolate.

A: The cocoa beans have been fermented. It needs to be destone, and classified. Normally the roasting temperature is 120℃ and the water content needs to reach 5-7% after roasting.

Q3: Cocoa beans can produce cocoa powder and cocoa liquor, what is the percentage of cocoa butter?

A: Cocoa liquid weight after grinding = weight of cocoa bean after roasting*98%; cocoa butter ratio 40-45%, the remainder is cocoa powder. generally, cocoa butter is pressed by a hydraulic oil pressing machine, cocoa oil after cooling, it is a white solid, which is cocoa butter.

A: Cocoa powder can be packaged with a large-sized powder packaging machine. Generally, cocoa powder is used as industrial raw material, mostly for large packaging. Cocoa butter and cocoa liquid blocks are solid after cooling. Generally, they can be packed with a pillow packaging machine.

A: The rated power of all equipment is added, that is the rated power consumption of the production line.