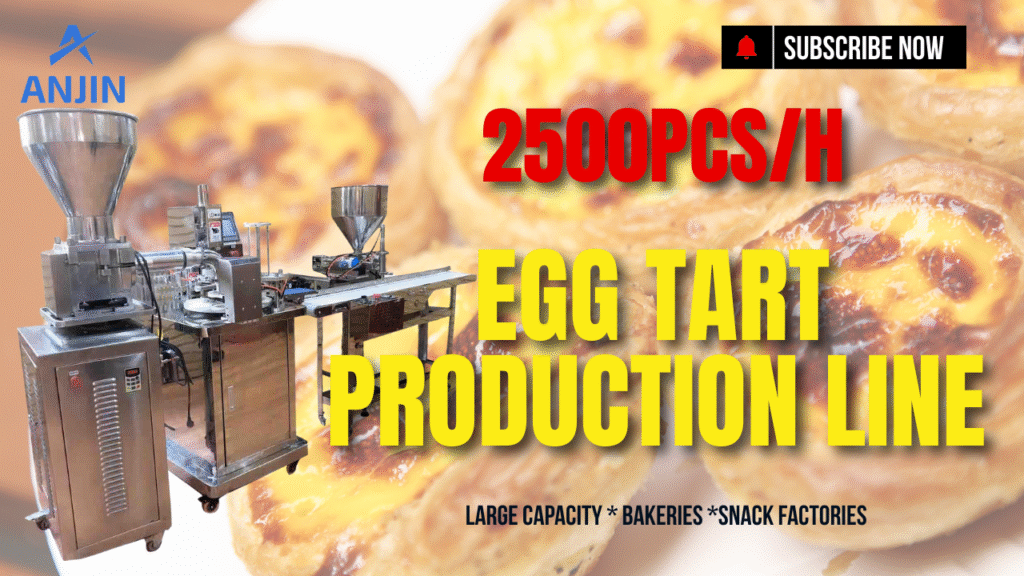

Egg Tart Production Line – Complete Solution by ANJIN FOOD MACHINERY

Golden on the outside and soft within — the egg tart is a global favorite for its crispy crust and rich custard filling. Behind this delicacy lies a highly automated production system that ensures precision, efficiency, and quality at every step. ANJIN FOOD MACHINERY provides professional equipment and solutions for commercial egg tart production, helping manufacturers achieve high capacity with consistent results.

🏭 From Dough to Delicious Tarts

The ANJIN egg tart production line consists mainly of a Dough mixer machine, a dough feeding machine, a tart shell forming machine, an automatic filling system, and a baking preparation section. It features a compact layout, stable operation, and an easy-to-use control system. The line integrates dough pressing, forming, filling, and conveying into one continuous process, reducing manual labor and improving output stability.

By switching molds, users can produce Portuguese, Cantonese, or customized flavored tarts with uniform shape and quality. The modular design supports flexible production scales, making it ideal for bakeries, food factories, and industrial dessert lines.

Besides the tarts mentioned above, we can also provide the solution for the lid-covered egg tart. Our machine can automatically press the lid on the top of the tart and pin the holes on the sheet. If you still deal with such a kind tart manually, welcome to contact us to get the customized solution based on your product characters.

⚙️ Process Flow Overview

Dough sheet pre-pressing and shaping

Dough feeding and positioning

Repeated rolling and folding for elasticity-Portuguese tart

Final sheeting and thickness control-Portuguese tart

Dough cutting and tart shell forming

🔩 Core Equipment

1. Vacuum Dough Mixer

This mixer replicates the manual kneading effect under vacuum conditions, forming a strong gluten network quickly and evenly. The low-temperature environment prevents overheating, ensuring the dough remains elastic and hydrated. The system supports high water absorption (up to 46%), creating dough that’s smooth, stretchable, and ideal for layered pastry applications.

2. Automatic Tart Shell Forming Machine

The dough feeder machine will distribute the dough (about 20–35g, grams can be set according to the tart size) into molds, and the PLC-controlled system automatically presses, shapes, and demolds each tart base. With a capacity of 1,300–1,800 pieces per hour, it suits continuous, high-efficiency production. The touchscreen interface simplifies operation, while quick mold changes allow for multiple product styles. Automatic cup feeding and easy cleaning design reduce downtime and labor intensity.

💡 Why Choose ANJIN FOOD MACHINERY

ANJIN FOOD MACHINERY specializes in food processing automation and bakery equipment solutions. Our systems combine modular design, smart control, and energy-saving engineering to help clients:

- Improve production efficiency and consistency

- Reduce raw material waste and labor costs

- Ensure stable performance and food safety compliance

- Customize layouts to fit specific factory spaces and output requirements

Each production line is tailored to customer needs, with full technical support from design to installation and after-sales service.

📞 Get in Touch

Ready to automate your tart production?

Contact ANJIN FOOD MACHINERY today to customize your egg tart production line.

Let’s build a more efficient, intelligent, and profitable food manufacturing future together.