📋 Steps for Industrial Spring Roll Wrapper Machine

- Batter Preparation: Mix flour, water, cooking oil, and a small amount of salt in the following proportions (e.g., 50 kg flour: 67.5–77.5 kg water + 300–400 g oil + 250–400 g salt). Stir for 5 minutes, let it stand for 10 minutes, and repeat this cycle three times.

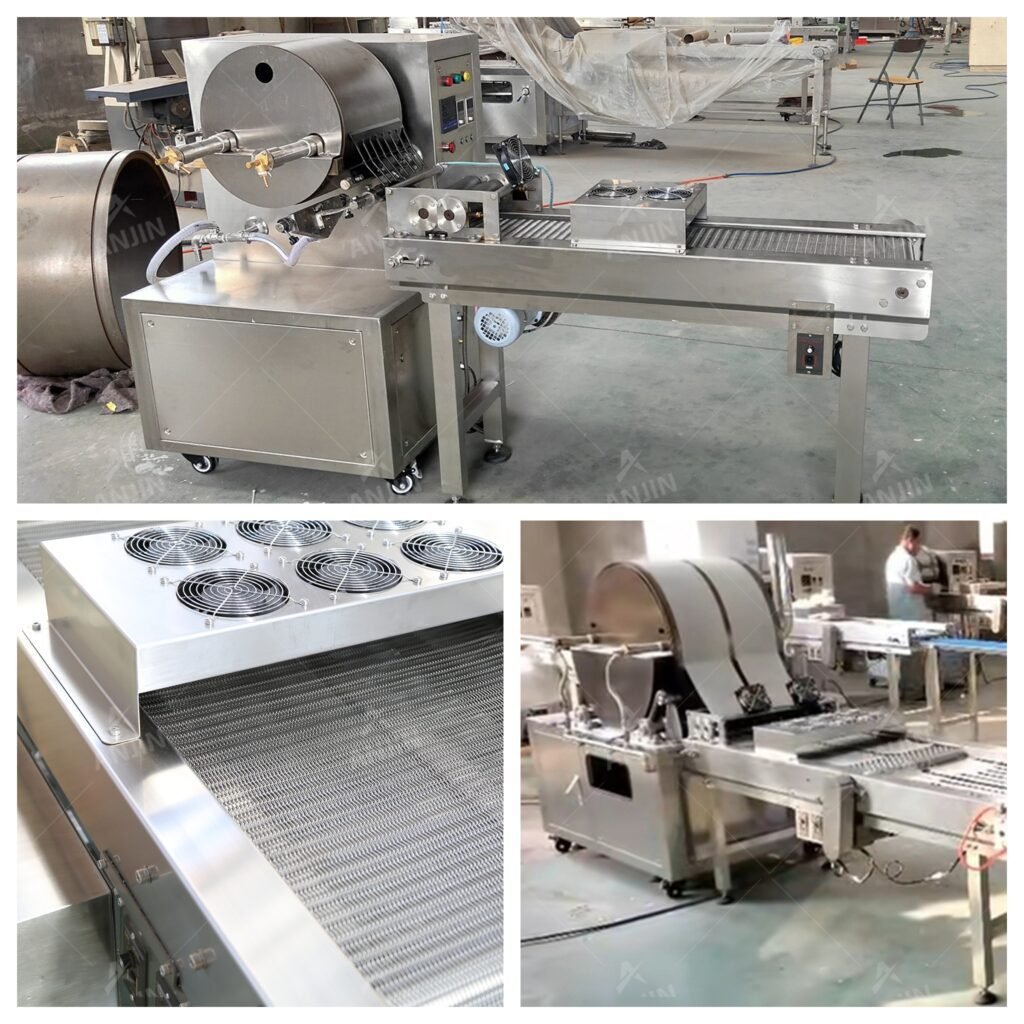

- Baking and Shaping: Feed the prepared batter into a trough, then spray it onto high-speed rotating baking rollers using a pumping system. The roller temperature is approximately 160°C (adjustable according to the process).

- Baking and Shaping: When the rollers rotate approximately 150-180 degrees, the batter is evenly heated, forming a spring roll wrapper of a fixed thickness, which then naturally separates from the rollers.

- Cooling and Conveying: The wrappers are automatically dropped onto a conveyor belt, then cooled or stacked, ready for subsequent packaging or filling.

✅ Machine Advantages and Features

- High Capacity: This type of machine performs exceptionally well in large-scale production. Depending on the model, its production efficiency can be very high.

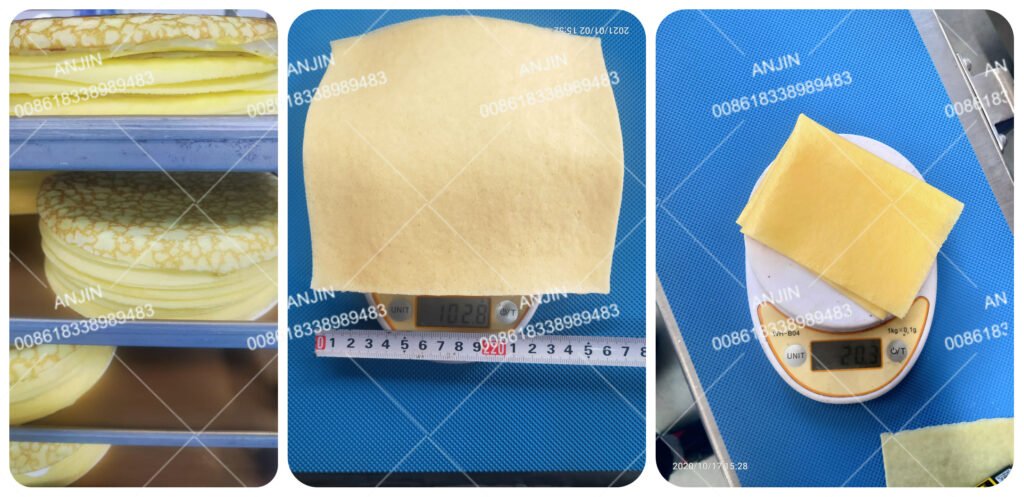

- Adjustable Skin Thickness: Wide range of skin thickness (e.g., adjustable from 0.3–1.2 mm) to meet the needs of different markets and products.

- Flexible Shapes: Can use different molds to produce round or square spring roll wrappers, increasing product diversity.

- Multiple Heating Methods: Supports electric heating, gas heating, and even resistance wire heating, adapting to different customer factory power conditions.

- High Degree of Automation: The entire production process requires only a few operators, saving labor costs and improving production efficiency.

- Hygiene and Safety: Food-contact parts are stainless steel (e.g., 304) and meet hygiene standards.

- Flexible After-Sales Service: Can choose with automatic folding mechanisms and counting devices to achieve a fully automated packaging production line.

✅ Installation and Usage Precautions

- During installation, ensure the machine is horizontal to guarantee stable performance of the hot roller and frame.

- During initial startup, preheat moderately and apply a small amount of cooking oil to the hot roller to prevent sticking.

- Suggest cleaning the slurry tank, nozzles, and rollers regularly, as the manual suggests, to ensure the equipment’s lifespan.

- The grounding connection must be correct to ensure safe operation of the equipment.

📊 Technical Specifications Reference

- Depending on the model, production capacity, machine size, and roller diameter vary. Some typical parameters are as follows:

- Output: 800–6000 sheets/hour

- Thickness range: 0.3–1.2 mm

- Heating roller diameter: 360 mm, 500 mm, 800 mm, 1200 mm, or even larger (for some models).

🔍 Why Choose ANJIN FOOD MACHINERY

- We offer customized solutions, tailoring molds, speeds, and heating methods to meet your production volume and product specifications.

- Having extensive export experience, serving the global market.

- Prioritize equipment stability, safety, and hygiene standards, rigorously controlling quality across all production lines.

- Provide professional installation, training, and after-sales service, helping customers quickly transition to automated production.

📞 Contact Us:

If you’re planning to build an industrial spring roll wrapper machine / a production line, or if your existing equipment isn’t efficient enough, feel free to contact ANJIN FOOD MACHINERY for a free consultation. We can recommend the most suitable machine configuration for you.